Product Introduction

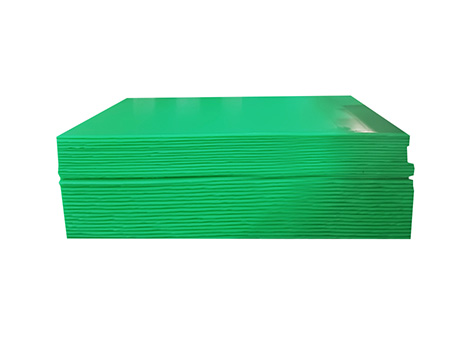

CNC UHMWPE Parts stand as a testament to precision engineering and material excellence. With customizable dimensions, a diverse color palette, varied thickness options, and applications across industries, these parts offer unparalleled advantages. Elevate your projects with CNC UHMWPE Parts – where precision meets perfection.

Product Advantages

- 01Precision in Dimensions

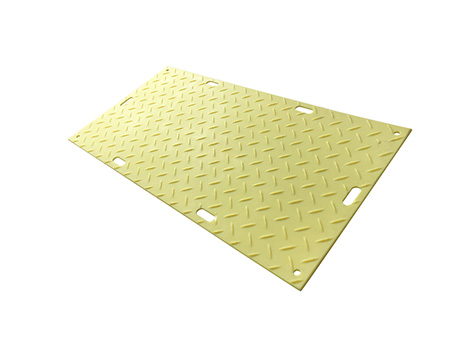

Our CNC UHMWPE Parts offer limitless possibilities with customizable sizes. Tailor the dimensions to meet the specific requirements of your project, ensuring a perfect fit and functionality. - 02Diverse Color Palette

Choose between the classic Natural (White) or unleash your creativity with custom color options. The versatility in color allows seamless integration into various applications, from industrial settings to artistic projects. - 03Varied Thickness Options

Select from a range of thickness options based on your application needs. Whether you require thin, lightweight parts or robust and heavy-duty components, our CNC UHMWPE Parts offer the flexibility to meet your specifications. - 04Material Mastery: UHMWPE

Crafted from Ultra-High Molecular Weight Polyethylene (UHMWPE), these parts embody the epitome of material excellence. UHMWPE is known for its outstanding strength, impact resistance, and self-lubricating properties, making it an ideal choice for precision CNC machining.

Product Applications

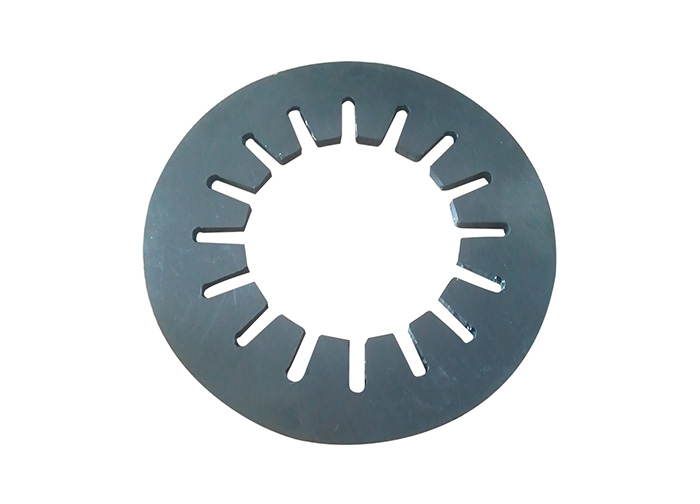

- 01Industrial Machinery Components

Utilize CNC UHMWPE Parts for manufacturing precision components in industrial machinery, ensuring longevity and optimal performance. - 02Conveyor Systems

Enhance the efficiency of conveyor systems with UHMWPE parts that offer low friction, reducing wear and extending the lifespan of the equipment. - 03Automotive Components

Benefit from the durability and low friction properties in automotive applications, from gears to sliding components, ensuring smooth operation. - 04Precision matters in medical equipment. UHMWPE parts are ideal for creating components with high wear resistance and biocompatibility.

Product Cases

Case 1: Industrial Overhaul

A manufacturing facility upgraded its machinery with CNC UHMWPE Parts, experiencing a significant reduction in maintenance costs and increased machine lifespan.

Case 2: Conveyor System Optimization

A logistics company implemented UHMWPE components in their conveyor systems, resulting in a substantial decrease in friction-related issues and improved overall efficiency.

Client Testimonials

Industrial Engineer: "The precision and durability of CNC UHMWPE Parts have revolutionized our machinery components, leading to increased productivity."

Logistics Manager: "Our conveyor systems have never run smoother. The low friction of UHMWPE parts has exceeded our expectations."

Related Products

Inquiry

If you need our products please write down any questions, we will reply as soon as possible.